With growing demands on the quality and speed of reinforced concrete product production, companies need solutions that ensure manufacturability, repeatability, and accuracy. One of the key elements of modern molding is magnetic formwork for reinforced concrete products — a technology that allows for flexible and accurate production with minimal labor costs and maximum efficiency. This system is particularly relevant for factories working with hollow floor slabs, beams, girders, and other linear products.

The essence of magnetic formwork technology

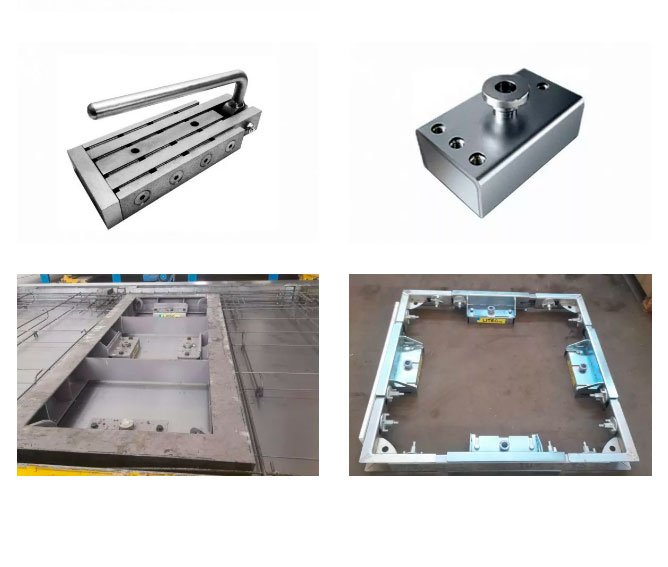

Magnetic formwork is a universal system in which the forming elements are fixed to a metal table using built-in magnets. The basis is a magnetic block with a magnetic force of 900 to 2100 kg, depending on the weight and length of the formwork used. A steel profile is attached to the magnet, which acts as the formwork edge.

The solutions used allow the edges to be precisely positioned and moved manually across the molding table without welding or additional fasteners. This simplifies the preparation process for pouring and increases the overall accuracy of the product geometry. Control is carried out by pressing a latch, which makes operation as simple as possible.

Application in the production process

In practice, magnetic formwork for the manufacture of reinforced concrete structures is used in the production of a wide range of products: from standard slabs to specialized structural elements. The technology allows for quick reconfiguration of molds for different product sizes and enables rapid adaptation to changes in production tasks.

Importantly, the magnetic system is compatible with most standard metal tables, making its implementation possible without major alterations or significant investments in infrastructure.

Advantages of the technology

The use of magnetic formwork provides the enterprise with tangible advantages:

- Significant reduction in the time required for installation and dismantling of molding elements;

- Increased manufacturing accuracy due to stable fixation;

- Reduced costs for consumables and welding work;

- Improved occupational safety by eliminating hot work on site;

- Possibility of repeated use without reducing the quality of fixation.

In addition, the elimination of welding and bolted connections minimizes deformation of the metal table, extending its service life.

Ready-made solution from TDM

TDM offers proven solutions in the field of formwork fastening. The range includes magnetic blocks and profiles adapted to the needs of real production. The formwork design is developed taking into account the dimensions and type of products, which allows you to achieve the best results from the first launch.

Magnetic formwork for reinforced concrete products from TDM is a reliable tool in the arsenal of modern manufacturers of reinforced concrete products. If you are looking for a way to speed up production, increase accuracy, and reduce costs, this solution is for you.

Contact the TDM team for advice and to select the magnetic formwork system that is best suited to your production needs.