In modern precast concrete manufacturing, the key success factors are speed, precision, and flexibility of production processes. In this context, innovative magnetic systems - specifically High‑Performance Magnetic Formwork Systems for Precast Concrete - have become a true breakthrough. They allow operators to quickly and securely fix side formwork elements onto the steel casting bed, dramatically simplifying the forming process and ensuring exceptional quality of finished products. Switching to magnetic fixation is not just modernization; it is a strategic decision that opens the way to high productivity and resource efficiency.

Precise Shape Control: Operating Principle of Magnetic Fixation Systems

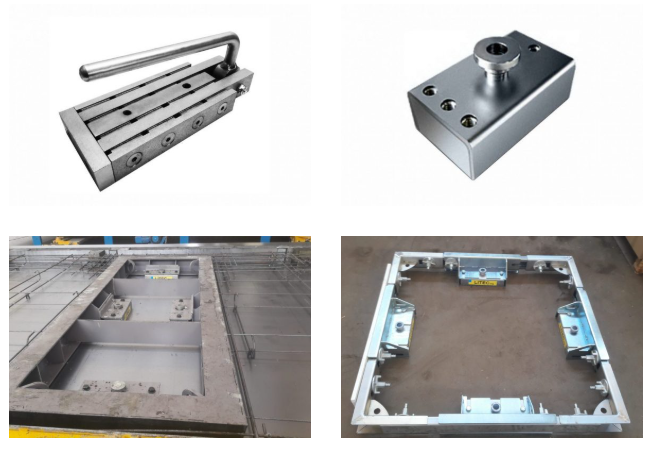

The core of magnetic formwork technology lies in the use of ultra‑powerful neodymium magnetic blocks integrated into specially engineered steel housings. These housings are attached to the side rails of the formwork system. When the magnetic block is activated, its tremendous clamping force securely fixes the formwork to the steel surface of the casting table or pallet. Unlike traditional mechanical fasteners (welding, bolts, clamps), magnetic fixation provides instant and extremely rigid anchoring, preventing any movement of the formwork even under concrete pressure and vibration. This guarantees stable geometry and high dimensional accuracy for all precast concrete products.

From Standard to Custom Projects: Application Areas of Magnetic Formwork

High‑Performance Magnetic Formwork Systems for Precast Concrete have gained widespread use in factories specializing in slipforming and a wide variety of precast structural elements. Typical applications include hollow‑core slabs, wall panels, columns, beams, and even bridge components. Thanks to their adaptability, magnetic systems enable rapid form reconfiguration for non‑standard or small‑batch production. Operators can easily reposition and install formwork side rails, creating products of various configurations—from simple rectangular shapes to complex architectural forms. Such flexibility is critical for companies striving for maximum diversity in their product lineup.

Undeniable Advantages: Why Manufacturers Choose Magnetic Fixation

Choosing High‑Performance Magnetic Formwork Systems for Precast Concrete is driven by several significant benefits:

- First, they significantly reduce reconfiguration and setup time. Instant fixation replaces hours of bolting, dramatically accelerating the production cycle.

- Second, they improve precision and quality by preventing formwork deformation and misalignment.

- Third, they increase the service life of the formwork itself since no drilling or welding is required, eliminating premature wear.

In addition, the use of magnetic systems enhances workplace safety and reduces qualification requirements for assembly personnel. This directly lowers production costs and increases overall profitability.

Choose a Proven Leader: Quality and Reliability for Your Production Facility

Modern precast manufacturing standards demand maximum efficiency. Using High‑Performance Magnetic Formwork Systems for Precast Concrete is not merely a trend but a necessity for maintaining competitiveness. We offer not just equipment but complete solutions based on proven Finnish engineering. Our magnetic fixation systems provide guaranteed holding force and long‑term durability, specifically designed for the most demanding production conditions.Contact us today to receive a customized quotation and start the modernization of your plant! Unique Value Proposition: We guarantee increased setup speed without compromising dimensional accuracy.

Frequently Asked Questions (FAQ)

1. What is the basic operating principle of magnetic formwork systems?

The principle is powerful fixation of formwork side rails onto a steel table or pallet using neodymium magnetic blocks. Fixation occurs through extremely strong magnetic attraction, ensuring stability even during concrete casting and vibration.

2. What advantages does magnetic fixation offer over bolted connections?

Key advantages include instant reconfiguration (significant reduction of setup time), improved dimensional accuracy, and extended formwork lifespan (no drilling or welding required).

3. How durable are High‑Performance Magnetic Formwork Systems?

With proper use, magnetic blocks typically last 10 years or more. They are resistant to vibration, moisture, and harsh industrial environments while maintaining their holding force.

4. In which precast products are magnetic systems most commonly used?

They are widely used in the production of hollow‑core slabs, wall panels, columns, beams, and other precast elements requiring frequent configuration changes and high precision.

5. How does magnetic fixation affect production economics?

Magnetic fixation reduces labor costs, shortens the production cycle, and minimizes formwork wear, all of which increase profitability.